Experimental Validation of the Oxide Model

This is a Discovery (Translational/Application) paper.

It is classified as such because the primary contribution is the experimental resolution of a long-standing scientific debate regarding the physical driving force of kinetic oscillations. The authors use established techniques (in situ X-ray diffraction and Debye Function Analysis) to falsify existing hypotheses (reconstruction model, carbon model) and validate a specific physical mechanism (the oxide model).

The Missing Driving Force in High-Pressure CO Oxidation

The study addresses the debate surrounding the driving force of kinetic oscillations in CO oxidation on platinum catalysts at high pressures ($p > 10^{-3}$ mbar). While low-pressure oscillations on single crystals were known to be caused by surface reconstruction, the mechanism for high-pressure oscillations on supported catalysts was unresolved. Three main models existed:

- Reconstruction model: Structural changes of the substrate

- Carbon model: Periodic deactivation by carbon

- Oxide model: Periodic formation and reduction of surface oxides

Prior to this work, there was no conclusive experimental proof demonstrating the periodic oxidation and reduction required by the oxide model.

Direct In Situ XRD Proof

The core novelty is the first direct experimental evidence connecting periodic structural changes in the catalyst to rate oscillations. Using in situ X-ray diffraction (XRD), the authors demonstrated that the intensity of the Pt(111) Bragg peak oscillates in sync with the reaction rate.

By applying Debye Function Analysis (DFA) to the diffraction profiles, they quantitatively showed that the catalyst transitions between a metallic Pt state and a partially oxidized state (containing $\text{PtO}$ and $\text{Pt}_3\text{O}_4$). This definitively ruled out the reconstruction model (which would produce much smaller intensity variations) and confirmed the oxide model.

In Situ X-ray Diffraction and Activity Monitoring

The authors performed in situ X-ray diffraction experiments on a supported Pt catalyst (EuroPt-1) during the CO oxidation reaction.

- Reaction Monitoring: They cycled the temperature and gas flow rates (CO, $\text{O}_2$, He) to induce ignition, extinction, and oscillations.

- Activity Metrics: Catalytic activity was tracked via sample temperature (using thermocouples) and $\text{CO}_2$ production (using a quadrupole mass spectrometer).

- Structural Monitoring: They recorded the intensity of the Pt(111) Bragg peak continuously.

- Cluster Analysis: Detailed angular scans of diffracted intensity were taken at stationary points (active vs. inactive states) and analyzed using Debye functions to determine cluster size and composition.

Periodic Oxidation Mechanism and Reversibility

Key Findings:

- Oscillation Mechanism: Rate oscillations are accompanied by the periodic oxidation and reduction of the Pt catalyst.

- Phase Relationship: The X-ray intensity (oxide amount) oscillates approximately 120° ahead of the temperature (reaction rate), consistent with the oxide model: oxidation deactivates the surface → rate drops → CO reduces the surface → rate rises.

- Oxide Composition: The oxidized state consists of a mixture of metallic clusters, $\text{PtO}$, and $\text{Pt}_3\text{O}_4$. $\text{PtO}_2$ was not found.

- Extent of Oxidation: Approximately 20-30% of the metal atoms are oxidized, corresponding effectively to a shell of oxide on the surface of the nanoclusters.

- Reversibility: The transition between metallic and oxidized states is fully reversible with no sintering observed under the experimental conditions.

Reproducibility Details

Data

The study used the EuroPt-1 standard catalyst.

| Type | Material | Details |

|---|---|---|

| Catalyst | EuroPt-1 ($\text{Pt/SiO}_2$) | 6.3% Pt loading on silica support |

| Particle Size | Pt Clusters | Mean diameter ~15.5 Å; dispersion $65 \pm 5\%$ |

| Sample Prep | Pellets | 40 mg of catalyst pressed into $15 \times 12 \times 0.3 \text{ mm}^3$ self-supporting pellets |

Algorithms

Debye Function Analysis (DFA)

The study used DFA to fit theoretical scattering curves to experimental intensity profiles. This method is suitable for randomly oriented clusters where standard crystallographic methods might fail due to finite size effects.

$$I_{N}(b)=\sum_{m,n=1}^{N}f_{m}f_{n}\frac{\sin(2\pi br_{mn})}{2\pi br_{mn}}$$

Where:

- $b$: Scattering vector magnitude, $b=2 \sin \vartheta/\lambda$

- $f_m, f_n$: Atomic scattering amplitudes

- $r_{mn}$: Distance between atom pairs

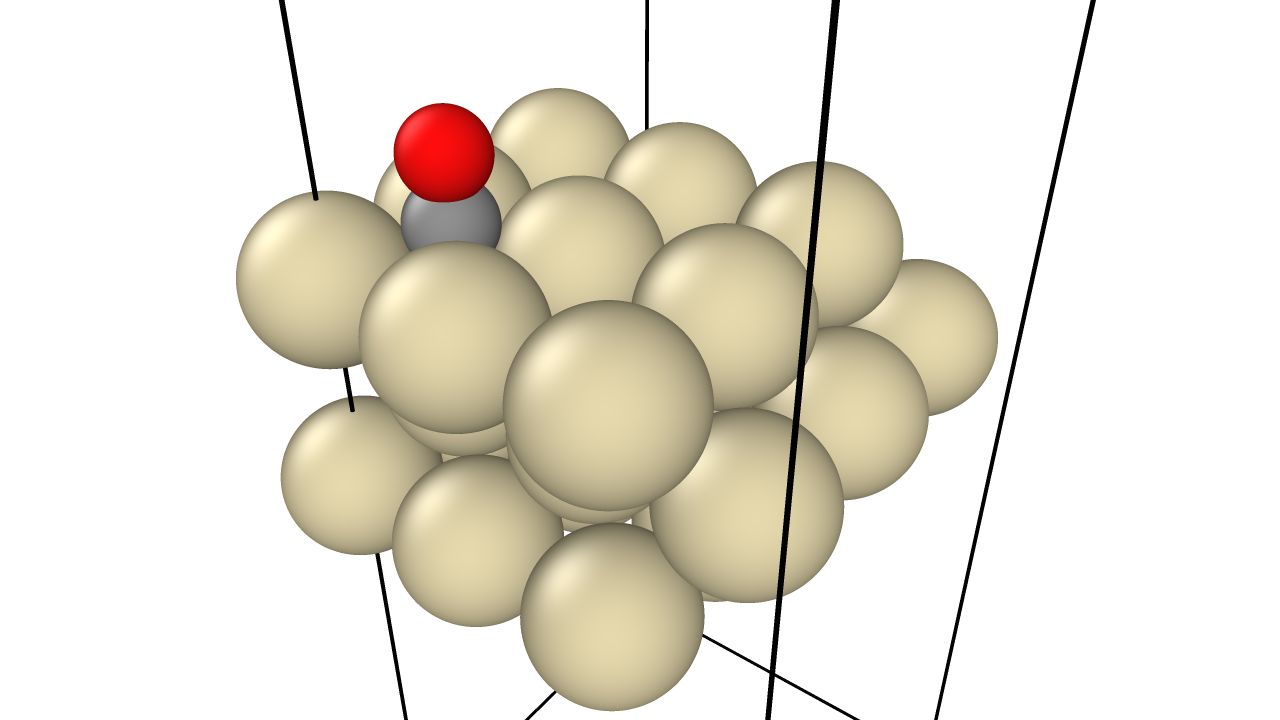

- Shape Assumption: Cuboctahedral clusters (nearly spherical)

Models

1. The Oxide Model (Physical Mechanism)

Proposed by Sales, Turner, and Maple, validated here:

- Oxidation: As oxygen coverage increases, the surface forms a catalytically inactive oxide layer ($\text{PtO}_x$).

- Deactivation: The reaction rate drops as the surface deactivates.

- Reduction: CO adsorption leads to the reduction of the oxide layer, restoring the metallic surface.

- Reactivation: The metallic surface is active for CO oxidation, increasing the rate until oxygen coverage builds up again.

2. Shell Model (Structural)

The diffraction data was fit using a “Shell Model” where a metallic Pt core is surrounded by an oxide shell.

Evaluation

Key Experimental Signatures for Replication:

- Ignition Point: A sharp increase in sample temperature accompanied by a steep decrease in Bragg intensity (~18-31.5% drop).

- Oscillation Regime: Observed at flow rates $\sim 100 \text{ ml/min}$. Below $50 \text{ ml/min}$, only bistability is observed.

- Magnitude: Bragg intensity oscillations of ~11% amplitude.

Hardware

Experimental Setup:

- Diffractometer: Commercial Guinier diffractometer (HUBER) with monochromatized Cu $K_{\alpha1}$ radiation (45° transmission geometry).

- Reactor Cell: Custom 115 $\text{cm}^3$ cell, evacuatable to $10^{-7}$ mbar, equipped with Kapton windows and a Be-cover.

- Gases: CO (4.7 purity), $\text{O}_2$ (4.5 purity), He (4.6 purity) regulated by flow controllers.

- Sensors: Two K-type thermocouples (surface and gas phase) and a differentially pumped Quadrupole Mass Spectrometer (QMS).

Paper Information

Citation: Hartmann, N., Imbihl, R., & Vogel, W. (1994). Experimental evidence for an oxidation/reduction mechanism in rate oscillations of catalytic CO oxidation on Pt/SiO2. Catalysis Letters, 28(2-4), 373-381. https://doi.org/10.1007/BF00806068

Publication: Catalysis Letters 1994

Related Work: This work complements Oscillatory CO Oxidation on Pt(110), which modeled oscillations via surface reconstruction. Here, the driving force is oxidation/reduction.

@article{hartmannExperimentalEvidenceOxidation1994,

title = {Experimental Evidence for an Oxidation/Reduction Mechanism in Rate Oscillations of Catalytic {{CO}} Oxidation on {{Pt}}/{{SiO2}}},

author = {Hartmann, N. and Imbihl, R. and Vogel, W.},

year = 1994,

journal = {Catalysis Letters},

volume = {28},

number = {2-4},

pages = {373--381},

issn = {1011-372X, 1572-879X},

doi = {10.1007/BF00806068}

}